IC manufacturing

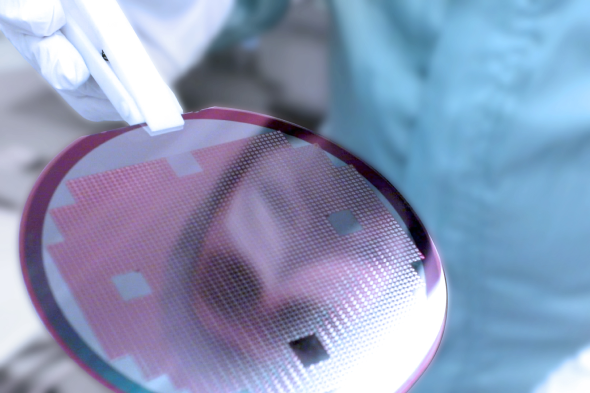

ZNTC provides full-cycle contract manufacturing of microelectronics and microsystem equipment (MEMS) for industry leading enterprises and start-ups, including engineering and manufacturing development, prototyping and full-scale production.

Abilities

ZNTC constantly modernizes its production facilities and carries out advanced training of employees to ensure high quality of ICs manufacturing.MEMS

sensors

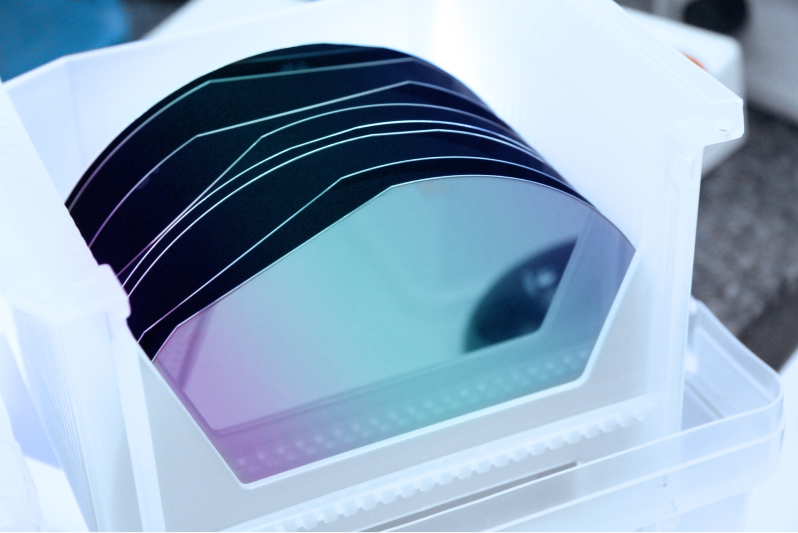

150 mm

wafer diameter

0,6 - 0,35 mm

design norms

Full manufacturing cycle

The set of manufacturing routes implemented by ZNTC allows to carry out a full cycle of technological services in the field of creating microelectronic products and microsystem equipment, as well as to implement individual technological operations of ICs manufacturing (manufacturing of VLSI, MEMS, SoC).

Services

- MEMS magnetoresistive sensors and transducers

- MEMS angular velocity sensors (gyroscopes, accelerometers)

- Integral photonics elements

- Power electronics (GaN-HEMT, IGBT)

- Pin diodes, NMOS

Advantages

- Ability to reduce customer costs

- for the manufacturing of ICs and MPW

- -projects, technology development and fine

- tuning of some product parameters.

- Completely Russian-made production

- at all stages of product manufacturing,

- including design, photomasking and ICs

- manufacturing and testing.

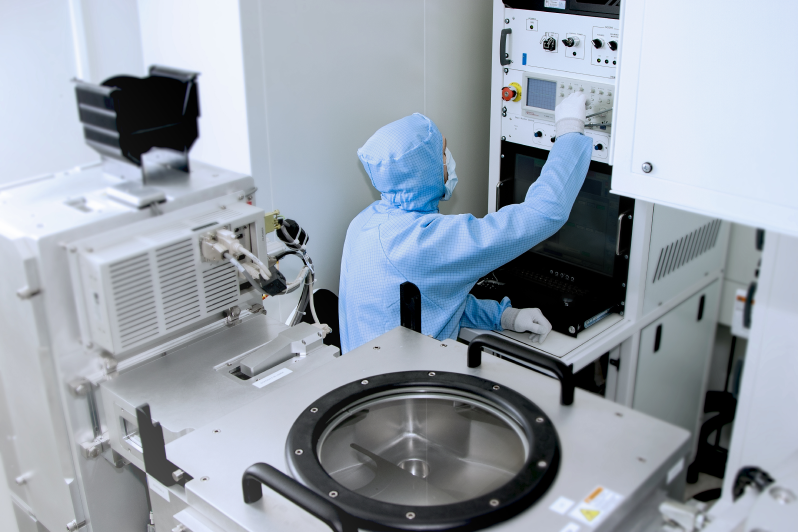

Technological capabilities

-

Bonding - debonding

-

Contact photolithographyon 150 mm wafers on a with the possibility of double-sided alignment

-

Atomic layer deposition (ALD)dielectric and conductive coatings, allowing the formation of multicomponent films with unique properties

-

Bosh-process of Si deep etchingat a speed of up to 15 μm / min

-

Projection photolithographyin the 1:4 scale on ASML 5500/300C stepper

-

CVD and PECVD processespoly-Si film application

of SiO2, Si3N4, -

Dry chemical etching process of semiconductors,dielectrics and metals

-

Spray wet cleaning processof semiconductors, dielectrics and metals in the solution

-

Rapid thermal annealfor electrical activation of the implanted interstitial diffusant and the silicide formation on the surface of active Si-structures

-

Ion etchingof metallic and non-metallic films such as iron, platinum, ferroelectric ceramics, etc.

-

Implantation of standard (B, P, As) ionsof energy range from 20 to 200 keV with the possibility of implantation of doubly charged ions on the IMC-200 installation. Dose range: from 1x1011 to 1x1018 cm-2.

-

PVD magnetron depositionof conductive dielectric and ferroelectric coatings with thicknesses from 1nm to 1200nm

-

Gas phase etchingof semiconductors and dielectrics to remove sacrificial layers in the MEMS manufacturing route.

-

Wafer sintering to form SOI structures

We always take into account customer needs and are ready to work on new interesting projects to expand our production capabilities.

Galina Shirkova

Head of IC manufacturing at ZNTC

Head of IC manufacturing at ZNTC

NEWTECHNOLOGIES

To implement innovative projects in the field of power electronics based on GaN(Si) and integrated photonic for telecommunications, we created a new technological infrastructure.

Get a commercial offer

Send your details and we will contact you

* Required fields